Release time:2025-04-25

Release time:2025-04-25

page views:10

page views:10

As a key hub for the north-south coal transportation, Zhuhai Port provides a reliable supply chain guarantee for storage and transit services to customers in South China, acting as an important "reservoir" in regional energy logistics. To enhance green development, Guoneng Zhuhai Port Affairs Co., Ltd. launched the Special Project for Environmental Improvement (Water Supply and Drainage) of Zhuhai Port, aiming to comprehensively treat coal dust and wastewater issues at the port.

As a leading comprehensive water treatment technology service provider in the industry, 9TONE Water has developed a tailored overall solution for coal-bearing wastewater treatment to address the insufficient collection and treatment capacity at Zhuhai Port. The solution greatly improves the port’s coal-bearing wastewater treatment capacity, effectively eliminates harbor basin pollution caused by direct discharge of coal-bearing wastewater into the sea during extreme weather such as heavy rainstorms, and supports Zhuhai Port in achieving green and sustainable development.

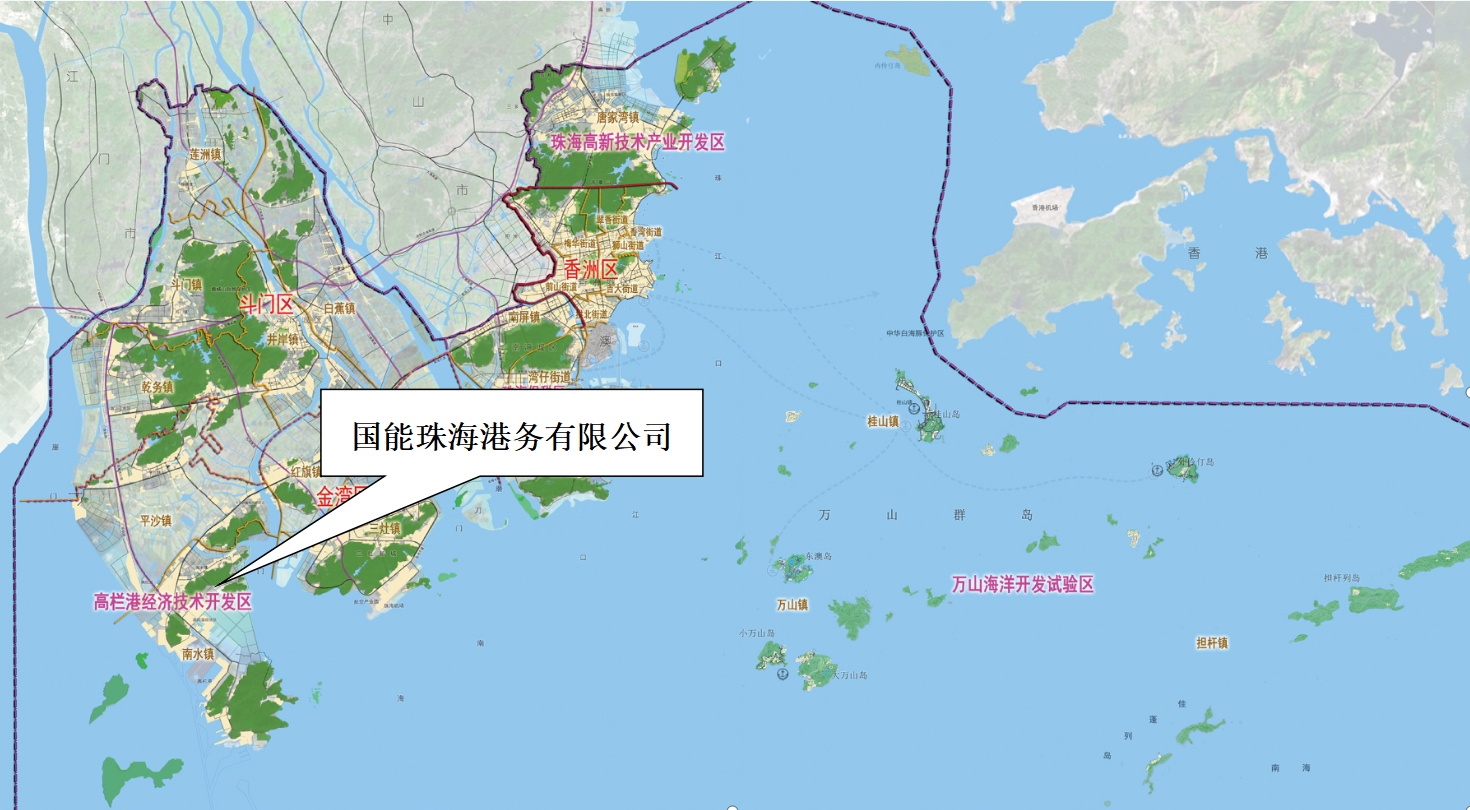

Project Location Map

Project Pain Points

01 Pain Point 1: Slag accumulation in windbreak nets causes perennial waterlogging

Drainage ditches around windbreak nets and sedimentation tanks inside the nets suffer severe coal slag accumulation, resulting in long-term standing water and reverse flow in some sections.

02 Pain Point 2: Heavy rainfall scouring leads to clogging of drainage ditches

During rainfall, runoff scours coal stockpiles and carries large amounts of coal lumps and slime into drainage ditches, causing serious blockages.

03 Pain Point 3: Severe drainage blockages impair coal-bearing wastewater collection

Severe clogging reduces effective drainage volume and prevents full collection of coal-bearing wastewater. During continuous rainfall, wastewater in regulating and sedimentation tanks cannot be treated in a timely manner.

Road drainage grates on the south side fully clogged with coal slime, causing surface water accumulation

9TONE Water | Overall Solution for Coal-Bearing Wastewater Treatment

01 Construction Scale

Guoneng Zhuhai Port Affairs Co., Ltd. currently operates one coal-bearing wastewater treatment station with a capacity of 530 m³/h. The newly built station is designed for a capacity of 13,320 m³/d.

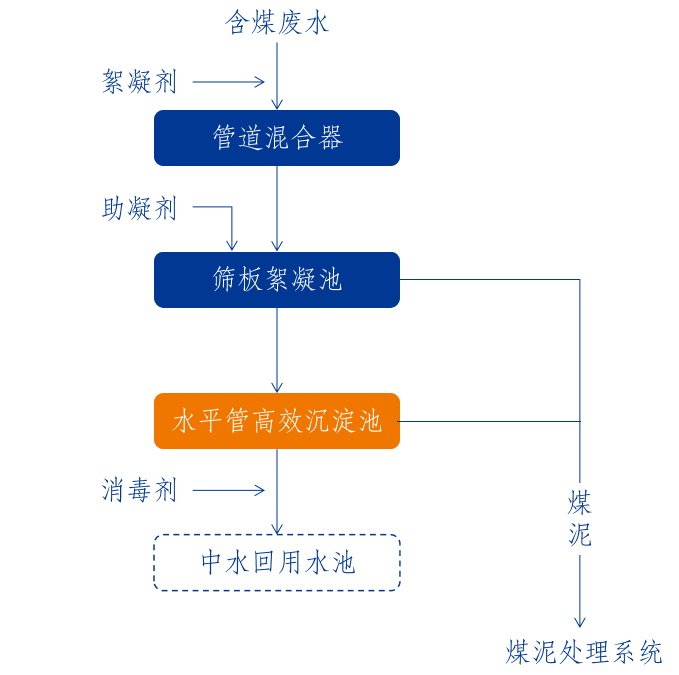

02 Process Scheme

Bar Screen → Primary Lift Pump → Pre-Sedimentation Regulating Tank (Horizontal Flow Type) → Secondary Lift Pump → Flow Meter → Tubular Static Mixer → Perforated Plate Flocculation Tank → Horizontal Tube High-Efficiency Sedimentation Tank → Reclaimed Water Tank

Process Advantages:

1. Rapid compliance treatment for surging coal-bearing wastewater during rainstorms, with advanced and mature process flow

The Horizontal Tube High-Efficiency Sedimentation Tank delivers high treatment efficiency, reducing retention time by 40%~50% compared with conventional processes, enabling rapid and compliant treatment of peak-flow coal-bearing wastewater during rainstorms.

2. Easy operation and management, low operating cost

The main process of the new system has no rotating equipment, requires no dedicated on-duty personnel, and involves minimal equipment maintenance.

3. Widely applied technology with successful cases across multiple sectors

The Horizontal Tube High-Efficiency Sedimentation Tank has been applied in a 25,000 m³/d water treatment project in Inner Mongolia under CHN Energy Group. Its applications cover municipal water supply, municipal wastewater, industrial wastewater, reclaimed water reuse, industrial water treatment, and black and odorous water remediation.

03 Process Design Water Quality Comparison

The effluent of the newly built coal-bearing wastewater treatment station complies with Level 2 of the Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB 18918-2002), and simultaneously meets Level 2 of the Local Standard of Guangdong Province: Limits for Discharge of Water Pollutants (DB44/26-2001) and the requirements for urban miscellaneous water specified in the Standard for Urban Miscellaneous Water Quality (GB/T 18920-2020).

The stricter limits among the three standards are adopted as the design effluent quality for this project, as detailed below:

04 Solution

Based on multi-dimensional analysis of client demands and scientific laboratory tests on on-site coal-bearing wastewater samples, 9TONE Water’s technical team confirmed that the design and construction of high-pressure water supply network replacement are mature. The key lies in the selection of coal-bearing wastewater treatment process. After comparison and evaluation, the high-efficiency combined process of Perforated Plate Flocculation Tank + Horizontal Tube High-Efficiency Sedimentation Tank is recommended.

1. Survey on-site topography and construct collection and pre-sedimentation tanks at suitable sections of existing drainage ditches, with structures consistent with original tanks

2. Clear silt deposits in existing drainage ditches to resolve insufficient wastewater collection and blockage issues in the plant area

3. Build high-efficiency coal-bearing wastewater treatment facilities to enhance treatment capacity and expand the wastewater system

Flow Chart of Expanded Wastewater Treatment System

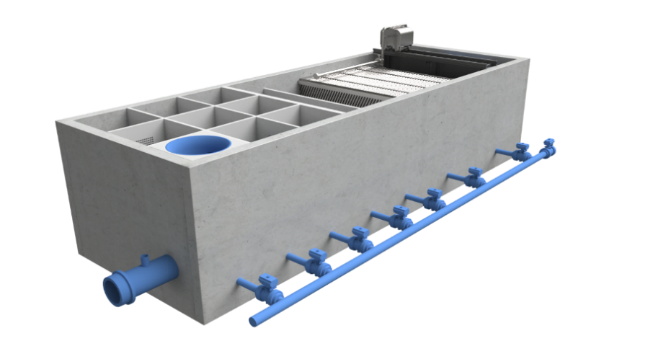

05 Core Product – Horizontal Tube High-Efficiency Sedimentation Tank

The Horizontal Tube Sedimentation and Separation Unit consists of multi-layer horizontally installed rhombic sedimentation tubes and sludge chutes inclined at 60° to the horizontal. It divides the vertical flow section into parallel sedimentation tubes and sludge discharge channels, separating sedimentation and sludge discharge functions.

As raw water (or flocculated water) flows horizontally through sedimentation tubes, particles or flocs settle vertically, slide along the tube bottom, and immediately enter sludge chutes through discharge ports, separating from the main flow and moving to the sludge zone at the tank bottom. This structure fundamentally solves the critical challenge of sludge discharge in horizontally placed sedimentation tubes.

Water flows through water channels, sludge flows through sludge channels. The design shortens settling distance, increases effective sedimentation area, and improves efficiency. It avoids the drawbacks of shared channels for sedimentation and sludge discharge, and optimizes conditions for reversible suspended solids removal.

Rendering of Horizontal Tube High-Efficiency Sedimentation Tank

Four Key Application Advantages of Horizontal Tube High-Efficiency Sedimentation Tank

1. No rotating equipment: Stable long-term compliant operation with low operating costs

2. No micro-sand or magnetic powder required: Energy-saving and eco-friendly, no secondary pollution to water bodies

3. Strong shock load resistance: High adaptability to fluctuating water quality and flow; can handle 10%–15% overload flow

4. Short commissioning period: Commissioning only takes 2–8 hours, with large potential for future upgrading

06 Implementation Effect

Treated effluent meets the reuse standard specified in GB/T 18920-2020 (Standard for Urban Miscellaneous Water Quality) and is directly sent to the plant’s reuse system for reclaimed water recycling. Coal-bearing sludge is dewatered to a moisture content ≤60% and transported to coal stockyards as coal cakes.

07 Project Site Overview

Project Benefits

The Zhuhai Port project effectively reduces wastewater discharge, realizes on-site reclaimed water reuse, lowers coal loss, and delivers both social value and economic benefits.

01 Improves urban water quality and residents’ living environment

02 Reduces water pollution control costs and avoids related economic losses

03 Supports the construction of a civilized and sanitary city and promotes urban economic and trade development